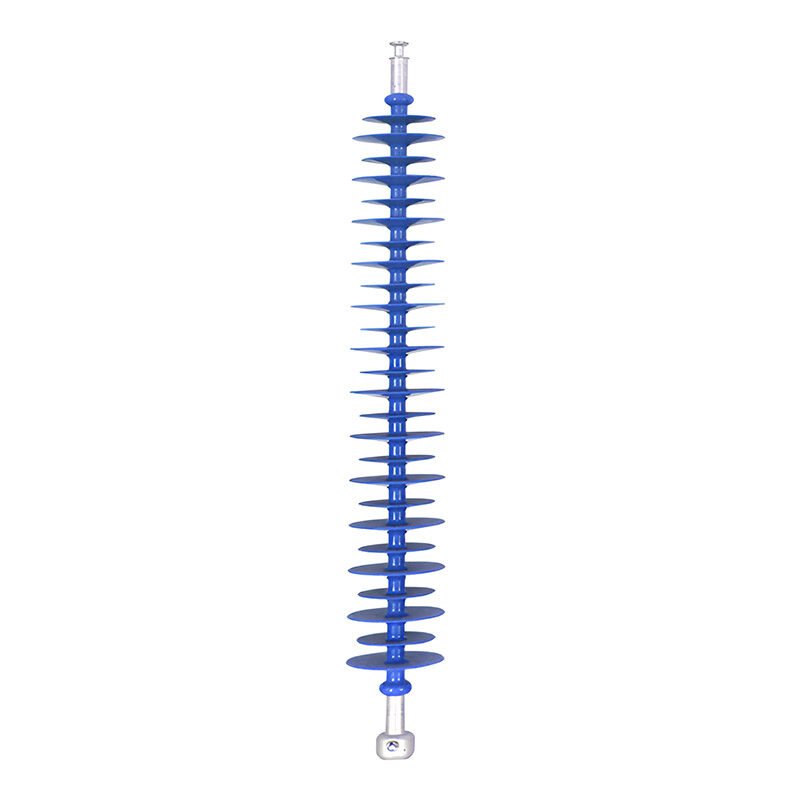

Composite Insulator

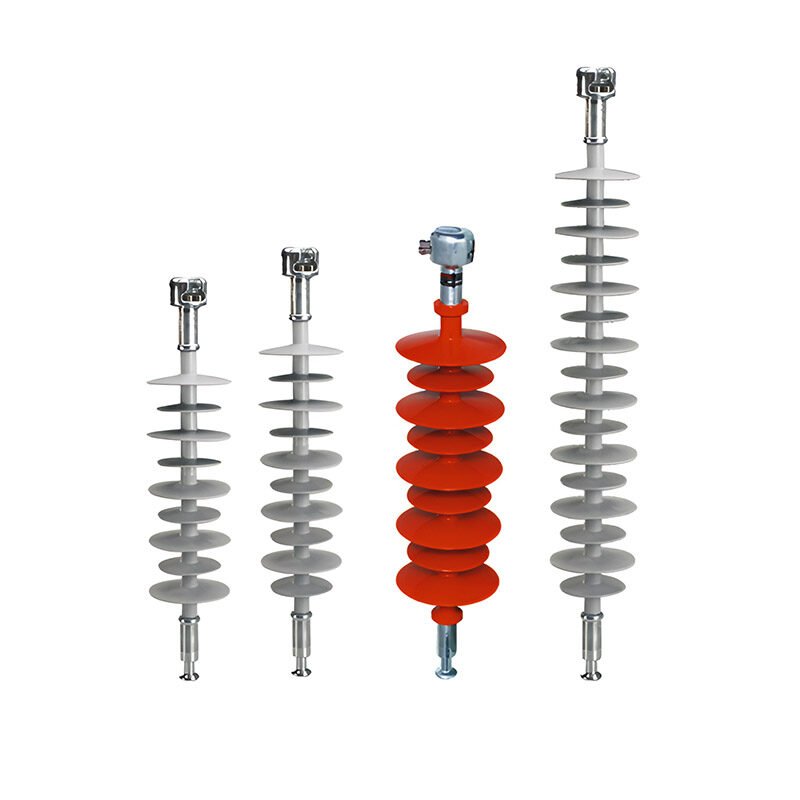

A composite insulator is a type of insulator that is made from a combination of rubber and metal. It is often used in power lines and other electrical installations. Composite insulators are a great way to protect your power lines and other electrical installations from damage. They are also very durable and can withstand a lot of wear and tear. Composite insulators are available in a variety of sizes and shapes, so you can find the perfect insulator for your needs.

Description

Composite Insulator

Advantages

- Lighter weight: They are significantly lighter than porcelain insulators, which makes them easier to transport and install. This is especially important for large transmission lines, where the weight of the insulators can be a major factor in the overall cost of the project.

- Higher strength: They are also stronger than porcelain insulators, which makes them more resistant to damage from wind, ice, and other environmental factors. This can help to reduce the number of outages and improve the reliability of the power grid.

- Improved electrical performance: They have a number of electrical performance advantages over porcelain insulators. For example, they have a lower dielectric constant, which means that they can withstand higher voltages without experiencing corona discharge. They also have a longer creepage distance, which means that they are less susceptible to flashover.

- Longer lifespan: They are expected to have a longer lifespan than porcelain insulators. This is because they are not as susceptible to corrosion and other forms of degradation.

Common Parameters

| Parameter | Value |

| Rated voltage | 11kV to 800kV |

| Mechanical strength | 70kN to 630kN |

| Creepage distance |

250mm to 3000mm

|

| Insulation resistance | ≥10000MΩ |

| Operating temperature | -40°C to +80°C |

Applications

Composite insulators are used in a wide variety of applications, including:

- Overhead power lines

- Substations

- Switchgear

- Transformers

- Wind turbines

- Solar panels